Electronic Manufacturing & Semiconductors

Navigate complexity across advanced manufacturing, global supply chains, and rapid technology cycles with precision, speed, and operational discipline.

STREAMLINED SOLUTIONS

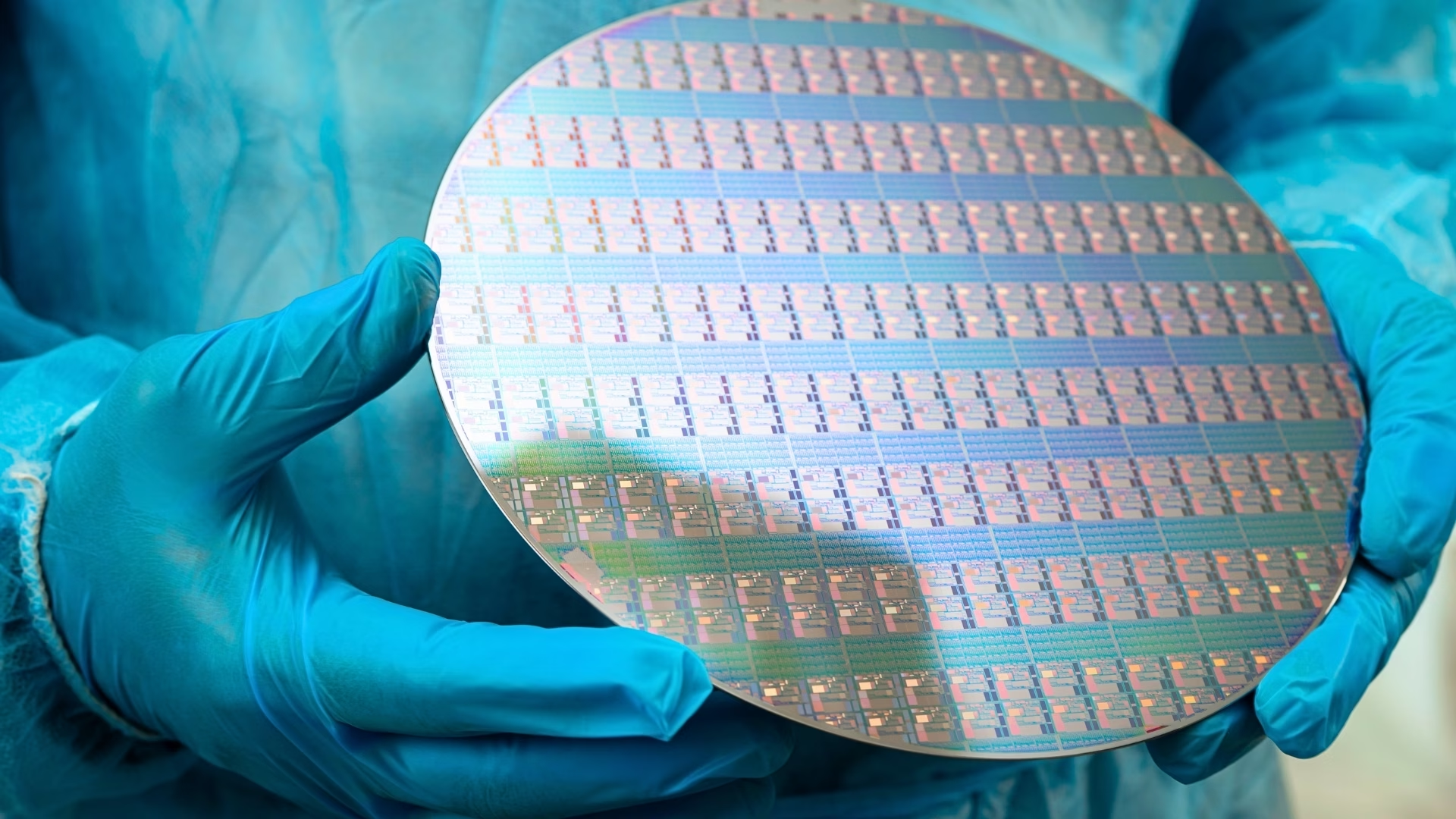

Power Performance Across the Semiconductor Value Chain

Electronic manufacturing and semiconductor companies operate at the intersection of capital intensity, extreme precision, and relentless innovation. Yield pressure, volatile demand, geopolitical supply risks, and shrinking product lifecycles leave no room for inefficiency.

VDS partners with semiconductor and electronics manufacturers to unlock operational performance across fabs, assembly and test, and downstream manufacturing, delivering measurable gains in yield, throughput, cost, and resilience while enabling scalable growth.

SERVICE EXCELLENCE

How VDS Gives You the Edge in Electronic Manufacturing

Industry-Vetted Problem Solvers

Our consultants bring deep, hands-on experience across semiconductor fabrication, electronics assembly, advanced materials, and high-mix manufacturing environments. We don’t advise from the sidelines, we embed with your teams to solve real operational challenges at speed.

OpEx® for High-Precision Manufacturing

From wafer fabs to PCB assembly and advanced packaging, we design and execute lean, data-driven operating models that improve yield, reduce cycle time, and stabilize output without compromising quality or compliance.

Systems That Sustain

We move beyond short-term improvements by building robust management systems, digital performance dashboards, and leadership capabilities that sustain results through technology transitions and market cycles.

SYSTEM THAT DELIVERS

Our Electronic Manufacturing & Semiconductor Services

VDS delivers Everything OpEx® to drive immediate gains and long-term excellence in industrial environments. We help private-equity-backed and middle-market manufacturers reduce costs, increase throughput, and build a scalable operations backbone.

Diagnostic & Roadmap Creation

Rapid enterprise and site-level diagnostics to identify yield losses, bottlenecks, variability drivers, and cost leakage, followed by a prioritized, ROI-backed execution roadmap.

Lean Process Redesign

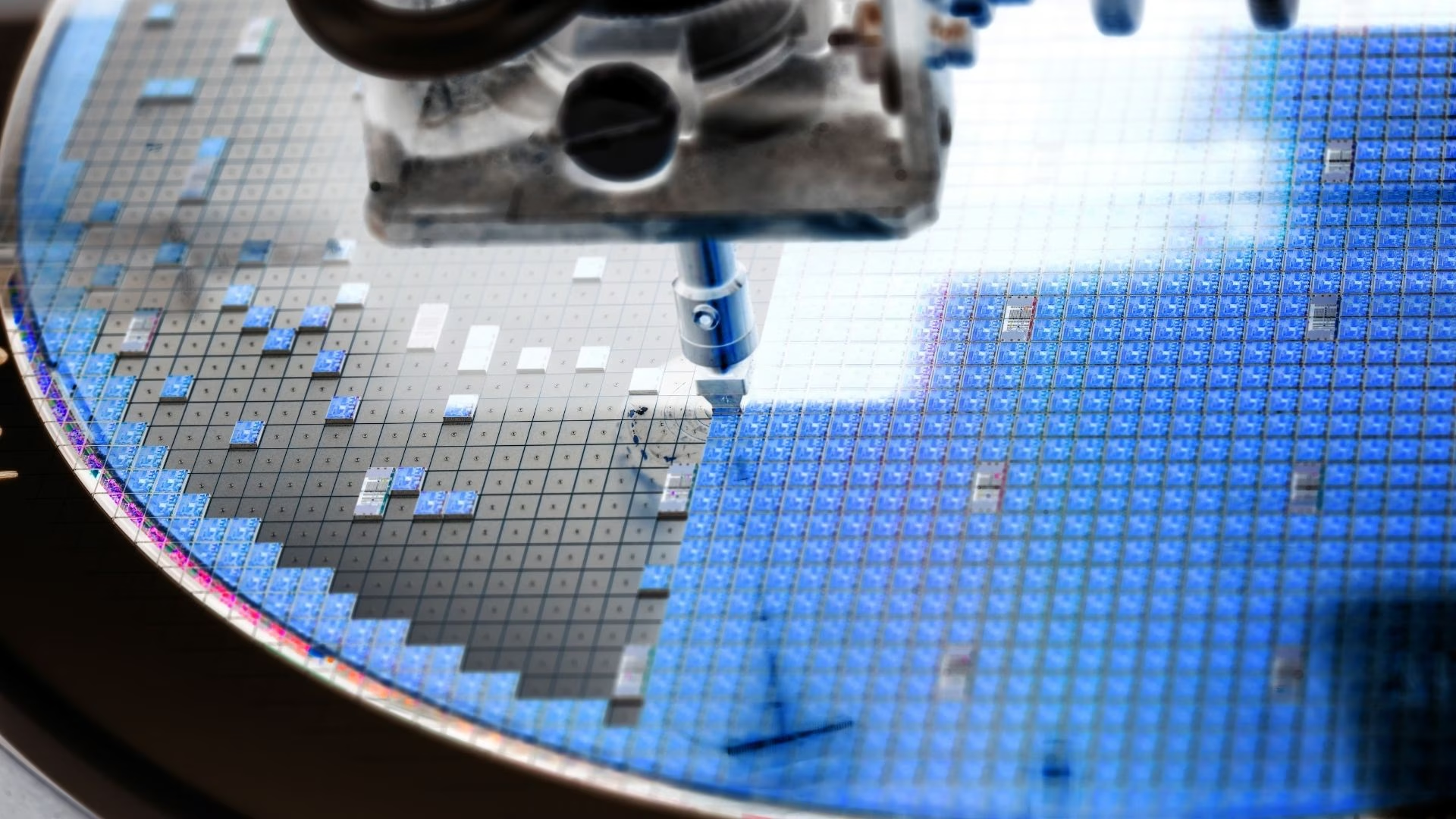

End-to-end flow optimization across fabrication, assembly, test, and logistics to reduce cycle time, WIP, scrap, and rework while improving on-time delivery.

Interim Experts & On-Demand Talent

Deployment of seasoned operations leaders, plant managers, yield engineers, and transformation leads to stabilize performance, lead changes, and accelerate execution during critical phases.

Training Built for Manufacturers

Targeted training programs for frontline leaders, engineers, and operators focused on problem-solving, statistical process control, variation reduction, and continuous improvement in high-tech environments.

8-STEP OpEx® APPROACH

High-Performance Operating Cycle for Semiconductor Operations

The VDS Eight-Step Operational Excellence approach is engineered to deliver sustainable transformation in electronic

manufacturing.

Define Value

Align operational priorities to client requirements, technology roadmaps, and financial objectives.

Establish Strategy

Translate business and technology strategies into clear operational targets and execution plans.

Develop Metrics

Design actionable KPIs that drive yield, throughput, cost, and reliability at every level of the organization.

Maximize Flow

Optimize material, information, and decision flow across fabs, lines, and networks to eliminate constraints.

Improve Quality

Embed defect prevention, root-cause problem solving, and statistical rigor into daily operations.

Eliminate Variation

Reduce process variability through standardization, capability development, and disciplined execution.

Analyze Results

Use data-driven reviews to identify gaps, validate impact, and course-correct in real time.

Share Success & Learning

Scale best practices across sites while building a culture of ownership and continuous improvement.

FAQs – Electronic Manufacturing & Semiconductors

We help improve yield, reduce cycle time, stabilize operations, and build scalable management systems across fabs, assembly, and test environments.

Yes. Our experience spans wafer fabrication, advanced packaging, electronics assembly, and high-mix manufacturing networks.

Initial performance improvements are typically delivered within weeks, with sustainable impact built over structured execution phases.

Yes. We deploy experienced interim leaders and technical experts to stabilize operations and lead transformations during critical periods.

We combine lean methodologies, statistical process control, root-cause analysis, and leadership capability building to reduce defects and variation.

Absolutely. We integrate operational excellence with digital tools, data analytics, and performance dashboards to accelerate impact.

PERFORMANCE

Delivering Measurable Impact in Electronic Manufacturing

Our approach generates measurable value across capital-intensive industries

Significant yield improvement for a semiconductor assembly and test operation through flow redesign and variation reduction

Cycle time reduction across high-mix electronics manufacturing lines enabling faster customer response

Inventory and WIP reduction through plant-wide flow optimization and demand alignment

Margin and EBITDA improvement for a PE-backed electronics manufacturer via operational turnaround and leadership stabilization

Drive Competitive Advantage in Semiconductor Operations

Analyzing every aspect of your business gives you an overview of where you are, where you need to make changes, and where you have already closed the performance gaps. This unique process is only available from VDS Experts and provides you with an aggressive, but feasible plan to move forward with.